Dragline Park

Wilkinson Coal Company John W. Page (Page Engineering)

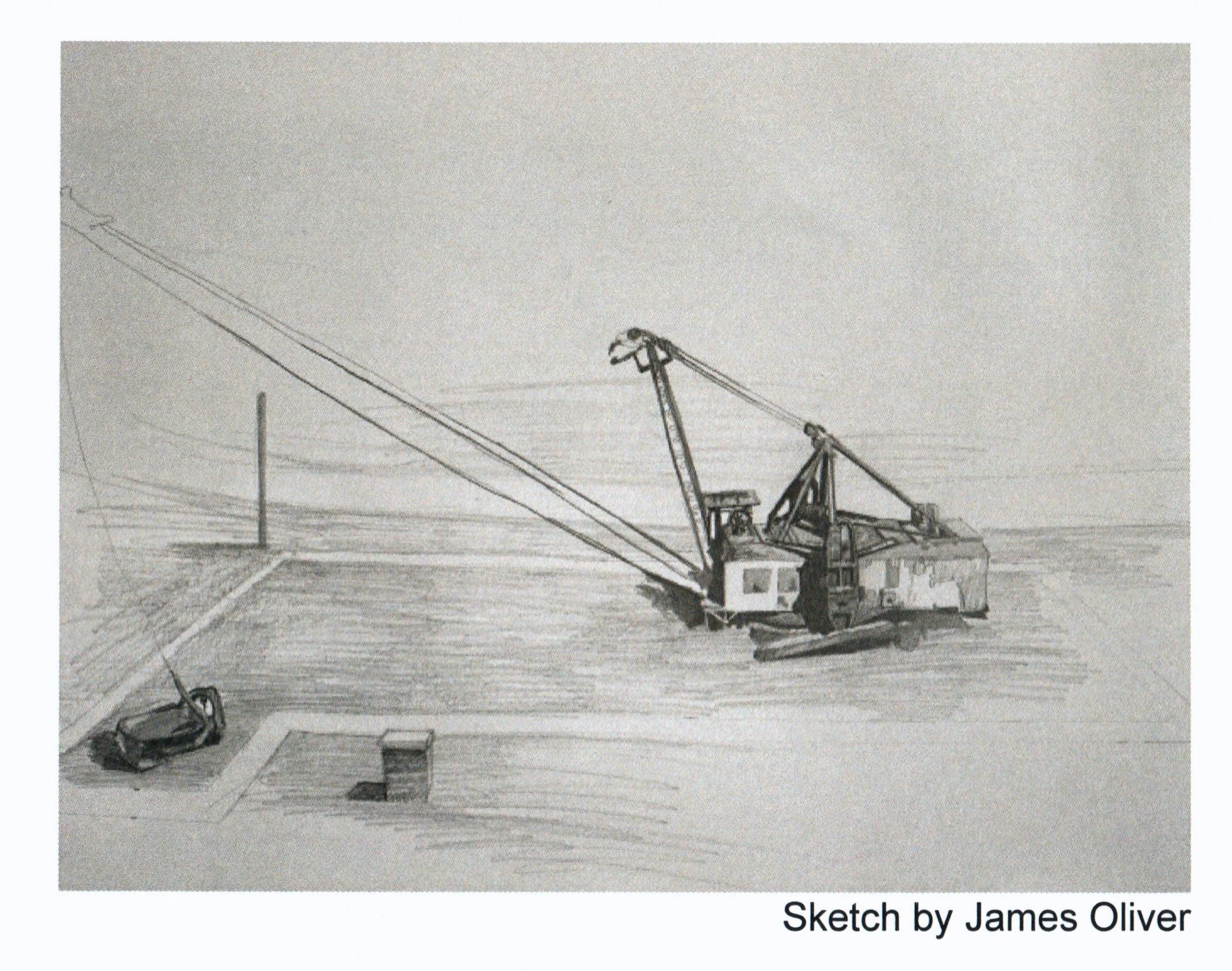

The Page 618 Walking Dragline is a nationally renowned one-of-a-kind piece of mining equipment. It will be located five blocks south of Miners Hall Museum in Franklin, Kansas at Dragline Park (junction of Hwy 69 & 47). It is the largest dragline and the only known Page 618 to be preserved for public display in the United States.

The Page is scheduled to be moved in 2025 to Dragline Park.

The Page 618 Dragline Project is funded in part by Kansas Tourism, the Patterson Family Foundation, the John U. Parolo Education Trust, the Coleman Family Foundation, and the Mitchelson Family Foundation.

The dragline will be located along the historic Jefferson Highway and adjacent to the National and State Historic Site “Franklin/Arma Sidewalk”.

A Wildflower Meadow will surround the Page 618 Walking Dragline and a Butterfly Garden will be a centerpiece of the parking area. Further information and plans will be coming soon.

In 1963, a grass fire touched off an explosion in a power magazine at themine. Four people were injured including Mr. and Mrs. Morris Wilkinson, and their son, Bill. The explosion destroyed the tipple, machine shop, the scale house, two storage buildings and nine company trucks.

The Wilkinson Coal Company continued to mine coal in Cherokee County until 1979 when EPA regulations required blending SE Kansas coal with Wyoming coal for a cleaner blend. It was no longer profitable to continue operation.

Wilkinson Coal Company, Weir City, Kansas, operated from 1917 to 1979.

The dragline was later used for clay mining by the Mission Clay Company. It later came back to the Wilkinson family when Wendell Wilkinson purchased it from Mission Clay.

Wendell and Lynda Wilkinson are donating the Page 618 dragline to Miners Hall Museum for the restoration project. The McNally Company and the Wilkinson Coal Company restored and preserved the Marion Model #37 Steam Shovel which can be seen at the Crawford County Historical Museum, Pittsburg, Kansas. A Page 222 Page Dragline has been restored and preserved and is on display at Big Brutus in West Mineral, Kansas. A dragline bucket is also on display at Miners Memorial at Immigrant Park in Pittsburg, Kansas. Another bucket is on display in Coal Camp at Miners Hall Museum.

With the completion of this significant project, a continuum of coal mining history will be achieved across the area’s coal fields in Southeast Kansas.

Wilkinson Coal Company

William Wilkinson was born in Pelton Fell, England, in 1862. He worked in the mines from the age of 10 and came to Weir City, Kansas, in 1883 at the age of 20 to continue mining.

In 1917, he started his own deep mine a mile south of Fleming, Kansas.

He and his wife, Mary, reared seven children who along with their spouses were active in the mining business during their lifetimes.

In 1923 the Wilkinson Coal Company started another mine one mile north of Weir City.

William Wilkinson died in 1932 and his sons continued the mining operation.

A Walking 618 Page Dragline with a 110-foot boom was purchased in 1953 from Alexandria, Louisiana, and shipped by rail to Weir City for the strip mining operation.

John William Page

In 1912, founded his engineering firm “Page Engineering Corporation” in McCook, Illinois. He perfected the first dragline bucket as a contractor on the Hennepin Canal. He was a member of the first graduating class of engineers at the University of Illinois in 1892. He served as President and Treasurer of Page Engineering until his retirement.

The dragline was invented in 1904 by John W. Page (as a partner of the firm Page & Schnable Contracting) for use in digging the Chicago Canal. By 1912, Page realized that building draglines was more lucrative than contracting, so he created the Page Engineering Company to build draglines. Page built its first crude walking dragline in 1923. These used legs operated by rack and pinion on a separate frame that lifted the crane. The body was then pulled forward by chain on a roller track and then lowered again. Page developed the first diesel engines exclusively for dragline application in 1924. Page also invented the arched dragline bucket, a design still commonly used today by draglines from many other manufacturers, and in the 1960s pioneered an archless bucket design. With its walking mechanism badly behind that of competitor Monighan (see below), Page updated their mechanism to an eccentric drive in 1935. This much improved mechanism gave a proper elliptical motion and was used until 1988. Page modernized its draglines further with the 700 series in 1954. Page's largest dragline was the Model 757 delivered to the Obed Mine near Hinton, Alberta in 1983. It featured a 75-yard bucket on a 298-foot boom and an operating weight of 4,500 tons. In 1988, Harnischfeger Corporation (P & H Mining Equipment)purchased Page Engineering Company.

Harnischfeger Corporation was established as P & H Mining in 1884 by Alonzo Pawling and Henry Harnischfeger. In 1914, P&H introduced the world's first gasoline engine powered dragline. In 1988, Page was acquired by Harnischfeger which makes the P&H line of shovels, draglines, and cranes. P&H's largest dragline is the 9030C with a 160-yard bucket and up to a 425-foot boom.